Process

We produce high quality productions with our technical capability, flexicibility, know-how, and consistent production system.

Mold Design, Production

Press Bending, Punching

- We process metal materials 1-5mm thickness bending and punching by press machines.

- We use progressive molds for reduction. It realizes cost reduction of products.

- You can order the multi-kind and the small lot production.

- We addopt original facilities which balanced the burden on worker reduction, security with work efficiency.

Press machine operators can take out punched materials efficiently without putting their hands between molds by our original mechanism.

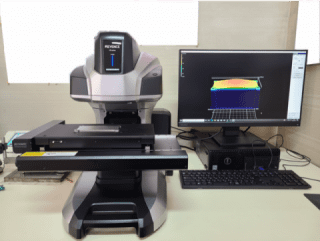

Warping

Washing

Resist Resin Printing

- You can order to print resist resin(UV hardened type) on base.

- We have the consistent process from pressing to printing, it makes be able to get more productivity.